Power Output

– Fiber Lasers

Fiber lasers can provide output power of 100W up to 50000kW. The output power has also improved in recent years due to constant technological improvements. Today, primary industrial machines use 30kW fiber lasers.

– CO2 Lasers

CO2 lasers are available in the power range of 100W to 25kW despite being large-scale lasers. While 50kW CO2 lasers are also produced, they are relatively more difficult and costly to manufacture than the other two types of lasers. They are also known to have higher power density than fiber lasers, with some CO2 lasers being even more potent than fiber lasers in some cases.

– Comparison

However, as we have seen, fiber lasers deliver less power than CO2 lasers in a given bandwidth, although the difference is narrowing with new high-power fiber laser models. As much as used in industrial applications of up to 25kW, both lasers can provide adequate power.

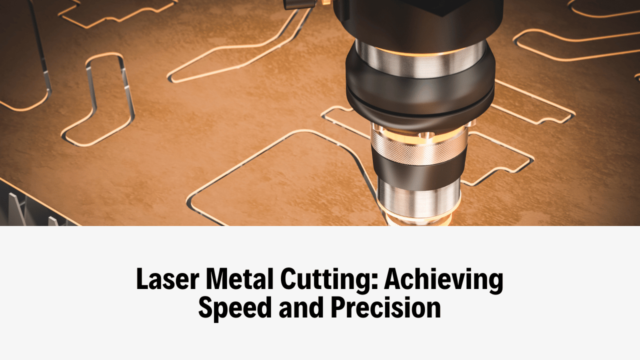

Precision and Focus ability

– Fiber Lasers

Fiber lasers employ glass fiber with small core diameters, which enables small spot size and more precision. The spot sizes can be as small as 5 microns and, therefore, very useful in fine cutting, welding, and micro-machining.

– CO2 Lasers

It is typically advised that CO2 lasers may produce spot sizes in the range of 50 to 100 microns. However, that is possible at small spot sizes, which need complicated optics and adaption systems. As for the cutting performance, the simple CO2 lasers are not as accurate as the fiber lasers.

– Comparison

In comparison to beam quality and spot size, fiber lasers are superior to CO2 lasers. As a result, they are ideal for use in applications that need accuracy, such as when cutting small holes or when creating delicate patterns.

Operating Costs

– Fiber Lasers

CO2 lasers have low EEo efficiency in the range of 10-15%, while fiber lasers have an efficiency of 30%. This can considerably cut down the total cost of running the business, especially in relation to electric power consumption. They also have long life spans, and little maintenance is required when compared to other types of fiber lasers.

– CO2 Lasers

General expenses of CO2 lasers are also high because their electrical to-light conversion is low; they use lasing gases, and they need frequent replacement of discharge tubes. The costs are incurred over years and therefore they are not all that cost-effective.

– Comparison

Cost of running a fiber laser system is much cheaper than that of a CO2 laser. Fiber lasers require less energy and less maintenance than other lasers.

Cutting Capabilities

– Fiber Lasers

Fiber lasers are versatile and can cut materials such as mild steel, stainless steel, aluminum, brass, and many others. Cutting with a fiber laser beam is precise and can meet strict tolerance. They can also successfully apply any reflective metals.

– CO2 Lasers

Furthermore, CO2 lasers are also able to cut all types of metals, including mild steel and aluminum. The cut quality is often slightly inferior to that of fiber lasers but usually is within the acceptable standard for most operations.

– Comparison

Putting into consideration the cutting aspect of industrial metals, both fiber and CO2 lasers are versatile in their operations. A fiber laser is capable of producing a higher quality cut. Also, it can handle materials which are reflective in nature. Interestingly, CO2 laser cutting is still sufficient for tasks that do not involve a level of precision beyond that of a few microns.

Maintenance Requirements

– Fiber Lasers

More diode pumps, fibers and optic components of fiber lasers are known to last for tens of thousands of hours with minimal maintenance. The downtime for fiber laser is far less than that in other laser machines.

– CO2 Lasers

CO2 lasers involve using such expendable parts as a discharge tube, gases and rf power supplies. They incorporate cleaning of optics. This translates into higher maintenance requirements than fiber lasers used in other applications.

– Comparison

So, in the context of this comparative review, it can be stated that fiber lasers have substantial practical benefits to CO2 lasers when it comes to reliability and the necessity of maintenance.

Conclusion

In conclusion, although high power CO2 lasers have some merits, fiber lasers are becoming more popular than high power CO2 lasers in many industrial applications. Since fiber laser cutting systems can produce higher beam quality with comparably smaller system configurations, they are the ideal systems to meet metal fabrication requirements. They are also cheaper to run than other trains and this make them affordable in the long run. It is anticipated that more advantageous applications will be unveiled in the future as the technology of fiber lasers advances.