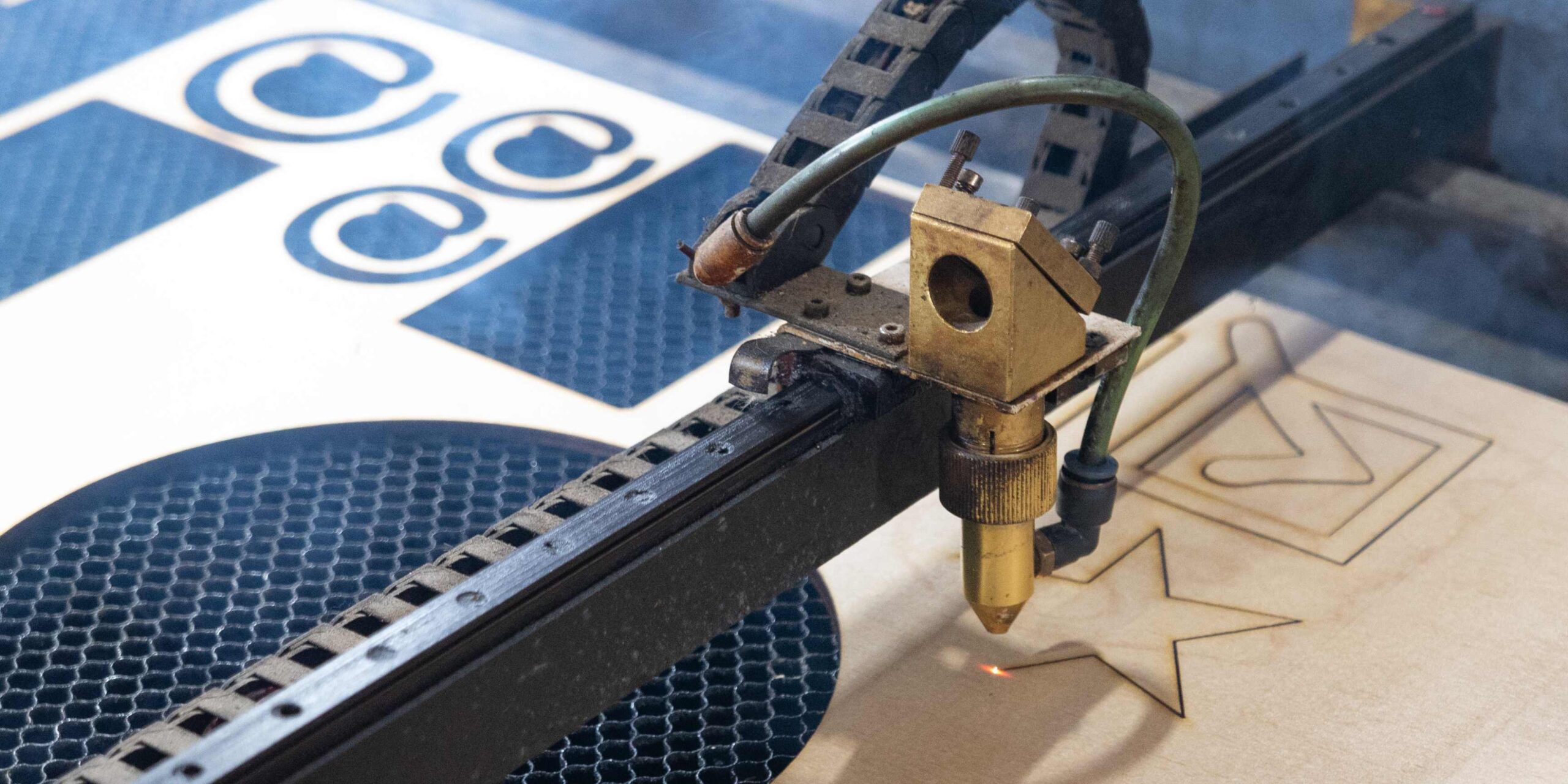

What is Laser Cutting Tolerance?

Laser cutting tolerance indicates the accuracy and the allowable variation in the laser cutter toward cutting the material. In terms of usability, it is the difference between the size of a cut as envisaged and the size actually obtained. Lack of tolerance led to the grounding and corrupting of input signals that, in turn, influences the quality and functionality of the final product. Therefore, a low tolerance level means there are small variations from the required dimensions of the object.

Reasons for Laser Cutting Tolerance

The tolerance limits in laser cutting, in general, depend on several factors. These factors need to be appreciated to advance precision and attain comparability of results.

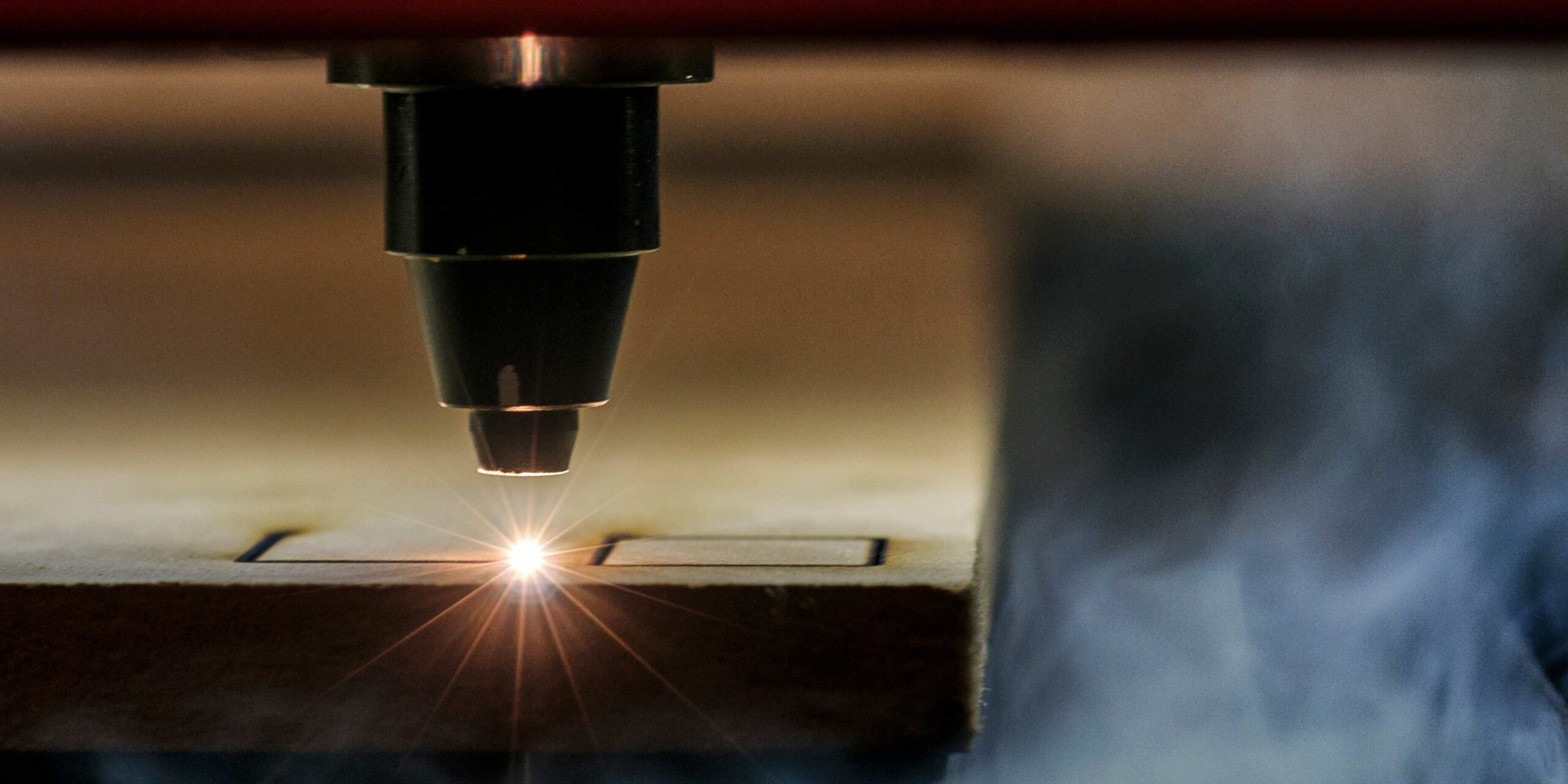

1. Material Type and Thickness

The nature and thickness of the material practically define the laser cutting tolerance. Laser energy is absorbed in different ways by different types of material, which damages the cut’s quality and accuracy. For instance, a larger material thickness may call for high power consumption, and time, resulting in deviations. Some of the basic materials afford high tolerance due to their uniformity, such as aluminum and stainless steel, but those such as wood or plastics can pose some problems.

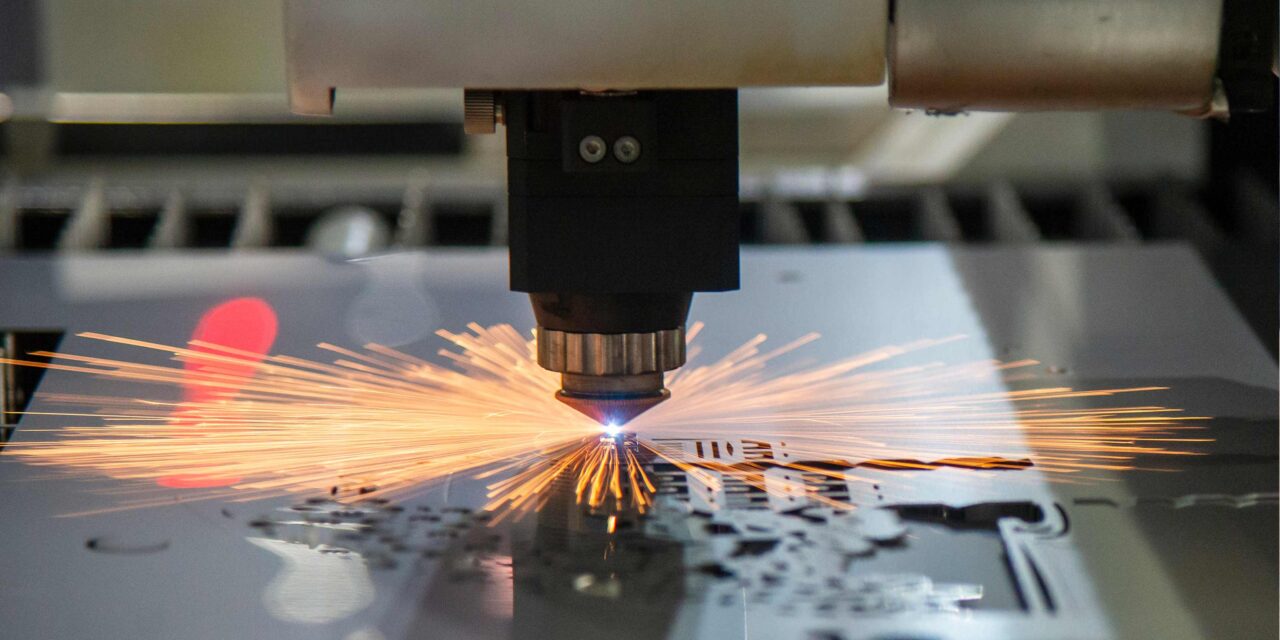

2. Laser Power and Speed

The tolerance levels depend highly on laser power and cutting speed within the manufacturing processes. Heat provides better edges and higher contrasts without a depressing effect on materials Likewise, the cutting speed has to be fine-tuned; if it is set too high, the cuts are not clean; if set too low, there is too much melt under the tool, which influences the tolerance.

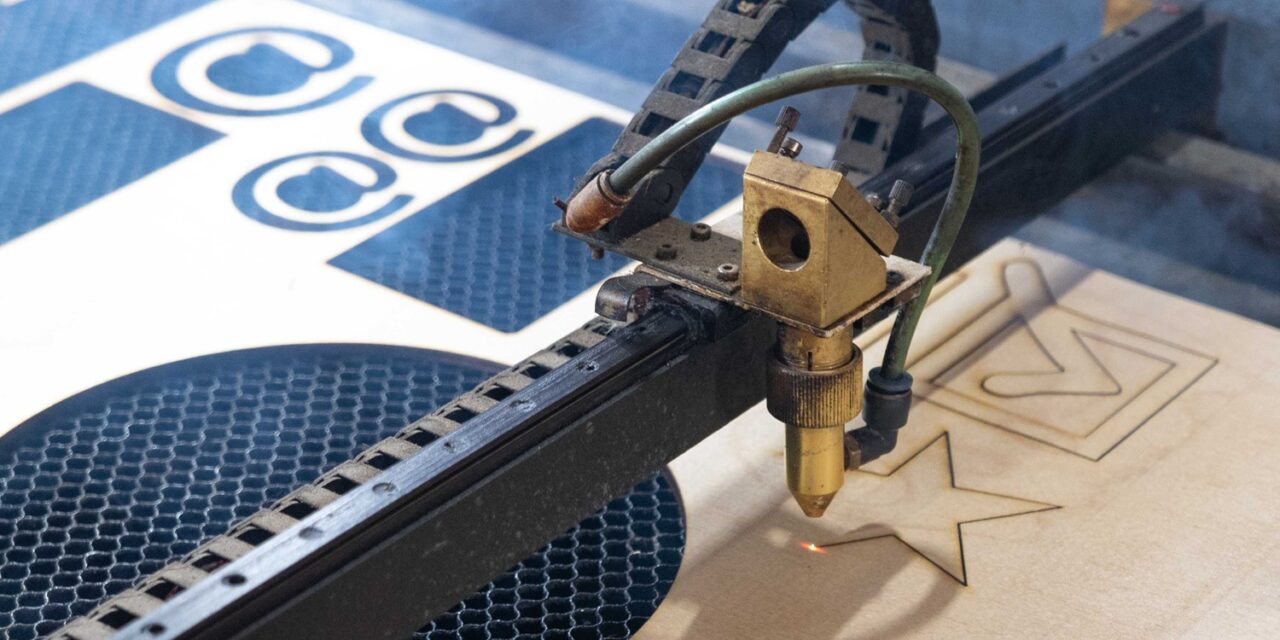

3. Focus and Alignment

Focusing and aligning the laser beam is crucial for high accuracy. Any deviation causes the blade to cut inaccurately and has low tolerance levels. Frequent adjustments of the laser cutting machine ensure that the laser beam is well-focused on the material to be cut.

4. Software and Design

The tolerance is impacted by the software used to design and control the cutting process of the whole program. Still, in Laser Cutting, complex CAD computer-aided design software gives one control over the path of the laser and the dimensions to be achieved on the material. It means any mistake made when working with the design file can easily culminate in an error in the resultant product.

5. Environmental Conditions

Other parameters, such as temperature and humidity, also appear to have some influence on tolerance during laser cutting.

Significance of Laser Cutting Tolerance

Achieving the right tolerance levels in laser cutting is crucial for several reasons:

1. Quality Assurance

High tolerance limits make it possible to obtain the necessary quality products. Tolerance standards in structural elements in sectors such as aerospace or automobiles are paramount to smooth functioning and component’s reliability.

2. Cost Efficiency

Poor tolerance levels may also result in more material being used than necessary, or incorrect parts being made. The concept of tolerance can be used to minimize wasted material, increase the yield ratio and, therefore, increase cost productivity.

3. Product Fit and Functionality

In assembly processes such as those applied in construction, the various components have to fit each other tightly. Fluctuation intolerance results in variation in form and size that affects the assembled product’s final output, integrity and sturdiness.

4. Customer Satisfaction

It is even more important that the obtained and required values should meet certain tolerance levels to satisfy the customer. Brand regulatory trust is created by consistent tolerance levels, which in turn affects manufacturers’ reputations.

Laser Cutting Tolerance Improvement

Managing acceptable tolerance levels requires both equipment, technique, and process control.

Here are some strategies to enhance laser cutting precision:

1. Regular Machine Maintenance

Machines should be maintained frequently to ensure the high performance of laser cutting machines. To do this, wipe lenses, align the laser beam, and make sure the mechanical components are in good shape. Equipment which is well maintained is less likely to generate deviations in the size of cuts to be made.

2. Preparation of the Materials

Selecting the material that best fits the job is important. It should be flat and in its best condition to avoid all hindrances during the cutting process. Proper preparation of the materials ensures that the results are consistently obtained.

3. Optimal Parameter Settings

These factors can indicate the right power and focus of the laser and the speed of the laser, which will provide the best results in a procedure. A series of tests should be run on the material and thickness of the size, and the parameter, along with the tolerance, should be set to the required criteria. Automatic systems could also control these parameters to improve consistency.

4. Software

The high-level CAD software will enable the cutter to exercise great control over the cutting process. Look at the design data incorporated into the design files and make sure it is correct.

5. Environmental Control

Stability of the working conditions might also help reduce temperature and humidity fluctuation, which impacts the cutting process. To achieve repeatable performance and maintain tolerance levels, it is advised that investments be made in climate control systems.

6. Skilled Operators and Training

A well-skilled operator enables the organization to achieve its productivity goals and objectives through training.

The tolerance level also depends a great deal on the knowledge that a skilled operator has regarding laser cutting technology. Proper training and frequent updating of systems help them deal with different materials and circumstances.