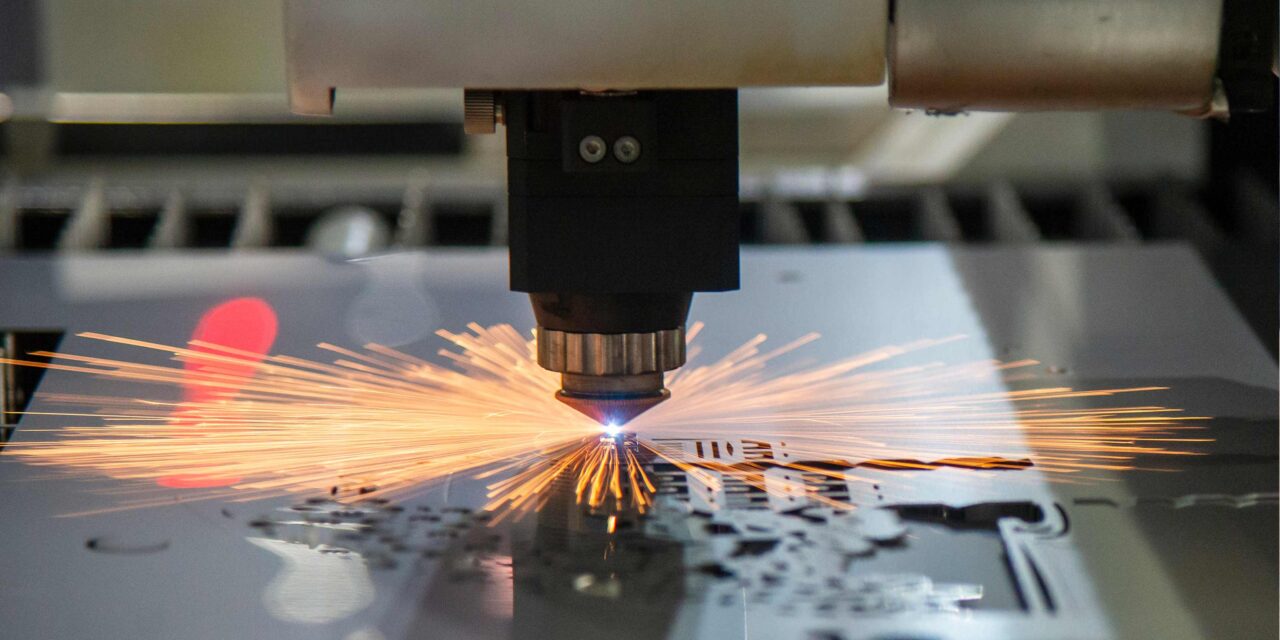

How Many Watts Laser to Cut Aluminum?

Learning More About the Difficulties Involved in Cutting Aluminum

It is a soluble material well suited to be used in numerous industries like Aerospace, Automotive, Construction, etc. When laser cutting aluminum several problems that must be taken into consideration when deciding on the correct power of the laser.

Reflective Surface

Aluminum in particular is highly reflective, thus when the laser strikes the surface, a great part of it is reflected back and little of the energy is actually absorbed by the material. On the other hand, this makes it less easy for the laser to melt and vaporize the aluminum, or (in general) the technology of cutting is poor or requires more laser power.

High Melting Point

One issue with working with the material aluminum for example is that it has a higher melting point than plastics so it cannot be cut with a typical laser. Second of all, aluminum, in general, is characterized by higher thermal conductivity, and therefore heat is immediately transferred far from the cutting zone, which makes the cutting even more difficult.

Criteria that Determine the Laser Power

Before the procedure aluminium ought to be evaluated and therefore the precise wattage of a laser ought to be chosen reckoning on the thickness of aluminium, speed, and quality of the cut.

Material Thickness

Thicker aluminum materials mind demands more laser power to offer a clean edge with no burr formed on the material’s surface. In general, as with thickness generally, more energy is needed to melt the material and vaporize it.

Cutting Speed

The desired cutting speed in the project to be done will also determine how much wattage the laser used will have. If greater cutting rate is needed, it might be essential to use a stronger laser in order to preserve cut quality.

Cut Quality

Edge finish and cut tolerance will also have a bearing on the power output of the laser; other characteristics. More power causes a better shave, and thus a cleaner cut than low power may cause a rough edge or even more dross.

Suggested Laser Wattage for Cutting Aluminium

These factors may be used in forming guidelines for general laser wattages used to cut aluminum.

Thin Aluminum

In case of thin aluminum materials which are less than 1mm thickness, a fiber laser with power of between 500 – 1000 watts is adequate in delivering a good cut. These lasers are precise and fast, therefore ideal for thin aluminum sections.

Medium-Thick Aluminum

For materials of mid thickness in aluminium, that is, thicknesses ranging between 1mm and 3mm, a fiber laser with power of between 1000W and 2000W is most suitable. This extra power of laser necessary to melt material rapidly, to remove the thin layer of the material and achieve the high quality of edge.

Thick Aluminum

For thick aluminum materials their thickness should be more than 3mm in which case high power laser cutter is required to make clean cuts and this could be with power from 2000w-3000w and above. These lasers can produce the amount of energy and the narrow focus necessary to sever through thick material in a good manner.

Additional Considerations

Apart from the laser power there are other parameter that can affect aluminum while cutting including the assist gas, focal length, and laser beam quality.

Assist Gas

As you continue cutting, the debris and dross from the previously cut area can dilute with the kerf, which can result in poor edge quality and material discoloration, hence by using an assist gas, such as nitrogen or oxygen, you get to increase the cutting efficiency, as well as help to vacuum the debris and dross from the cutting area.

Focal Length

The focal distance of the laser cutting head was optimized by varying and determining the appropriate focal distance for the different aluminum materials and their thickness. For a sharper beam and better cutting operation, a shorter focal length will be required for thicker materials.

Beam Quality

The quality of the laser beam used is essential while cutting aluminum since the use of a low quality beam reduces the efficiency of the cut made. In cutting aluminium, the quality of the laser beam used in the system has to be the best so that the proper cut is achieved.