Can a Laser Cutter Cut Metal

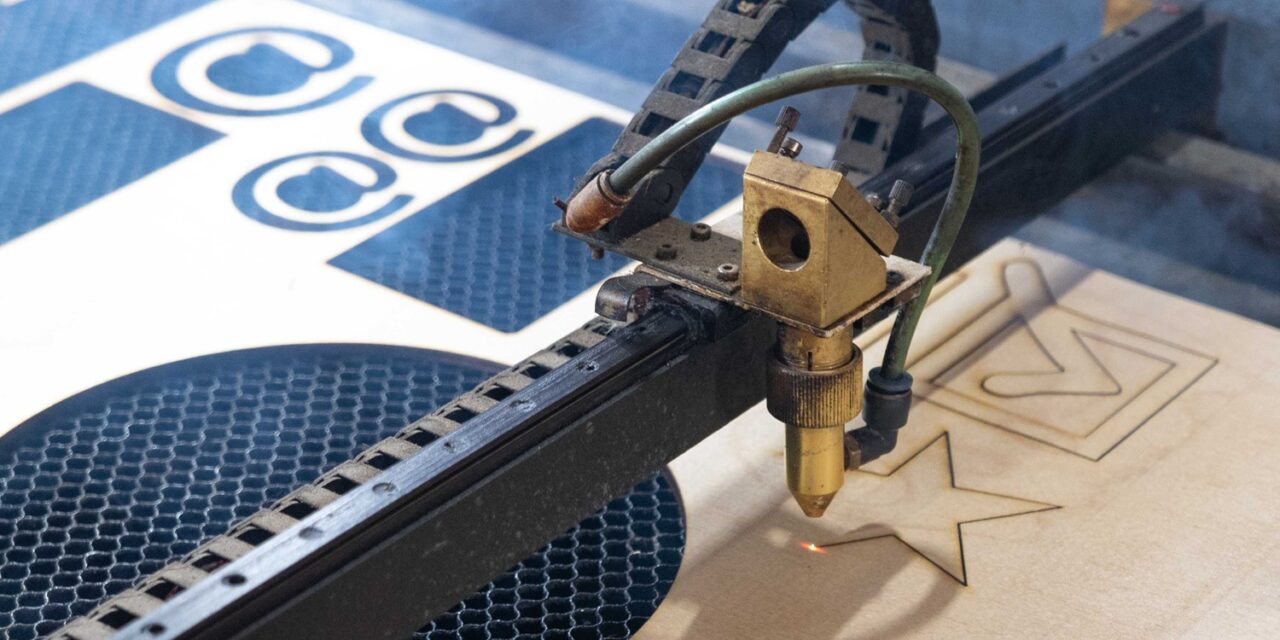

Laser Cutting Understanding

The process operates by conning a laser beam on a specific spot, and since the heat is concentrated, it melts, burns or vaporizes the material. To cut material, a stream of gas, which may be nitrogen or oxygen, is used to eject the molten material. Because of efficiency and accuracy, and they are able to cut complex shapes.

Lasers for Metal Cutting.

CO2 Lasers

Carbon dioxide or CO2 lasers are widely used in laser cutting among all types of lasers. The generation of the laser beam is accomplished by these lasers using a gaseous medium, carbon dioxide being the most popular. The CO2 laser is well suited for cutting and engraving non-metal materials such as wood, acrylic and textiles but is not so efficient in cutting metals. This is because the metal absorbs less of a CO2 laser, which makes it a slow process of cutting and processing compared to using a fibre laser.

Fiber Lasers

Fibre lasers are commonly used to cut metals because of their high performance as compared to other laser cutting technologies. These lasers employ a fibre optic cable whose core is subsequently doped with rare earth compounds, namely ytterbium. Fibre lasers have a higher absorption factor in metal and are hence used in the cutting of steel and other ferrite metals. It provides opportunities for higher cutting speed, higher accuracy, and lower operations costs, in contrast to the CO2 lasers.

Nd: YAG Lasers

Another laser-cutting metal option is the Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) lasers. They are multifunctional and work for cutting and welding, and they are strong for marking. Although they can cut a range of materials, including stainless steel and aluminum, fibre lasers are normally more efficient. However, they are ideal when used to cut non-ferrous materials and other complex shapes and designs.

Metals That can be Laser Cut

Steel

Laser cutting’s most extensively utilized metal is steel, especially carbon steel. Fibre lasers are ideal for this procedure because of the high absorption coefficients. Compared to other cutting techniques, laser cutting of steel offers clean edges and is hence preferred by the automobile, aircraft, and construction industries.

Stainless Steel

Cutting stainless steel with a laser requires more tweaks to the settings and the coolant necessary to prevent oxidation. Stainless steel, however, has some drawbacks inherent to its reflective surface, but fibre lasers can solve these problems due to their high efficiency in the absorption of such material.

Aluminium

Another conductor that is easily cut with the laser cutter is aluminium. It is non-ferrous and has rather good thermal conductivity, and therefore, it rapidly removes heat from the material. All this can make the laser out of focus and end up being less accurate. However, under laser and efficient material cooling conditions, aluminium can be cut with extremely high accuracy.

Copper and Brass

Both copper and brass are difficult materials for laser cutting due to their qualities as heat conductors and reflectors. It could be possible, however, to use a high level of laser cutter and specific parameters. These metals usually work using lesser proficiency lasers or water jet-cutting methods for improved outcomes.

Titanium

It has high strength and low density, which explains why it is used in aerospace machines and medical equipment. Cutting titanium by laser is difficult because of its high melting temperature and tendency for oxidation during cutting. Small laser machines with micro-stepping and laser cooling options allow for getting clean cuts.

Benefits involved in Laser cutting metal

Laser cutting offers several advantages over traditional metal cutting methods:

– Precision: Laser cutting can produce some very accurate cuts, accuracy or repeatability being usually within .005mm.

– Complexity: The advantage of using a laser cutter is that it can cut out very detailed shapes (and even combine many of them to build complex forms).

– Speed: Laser cutting is also quicker, particularly when using a fibre laser for materials such as metal steel.

– Clean Edges: It creates smooth edges that rarely need a lot of enhancement work to be done.

– Versatility: Laser cutting technologies work effectively on different types of metals.

Some Drawbacks of Using Laser Cutting Metal

While laser cutting metal has numerous benefits, there are limitations to consider:

– Thickness: Laser cutting machines, however, have a limitation on how thick the metal being used is. Thick metal needs more power lasers and time to cut than thin ones.

– Reflectivity: Highly reflective metals, such as copper and aluminum tend to reflect off the surface, which in turn damages the cutting system.

– Oxidation: Some materials, such as stainless steel, are prone to oxidation during laser cutting unless controlled by gas.

– Cost: It has been established that fibre laser-based high-power laser cutting systems are expensive to acquire and use.

Laser cutting has been taken to the next level, giving high levels of accuracy, speed and flexibility in metal cutting. While CO2 lasers are less effective for cutting metals, fibre lasers and Nd: YAG lasers are effective for all steels, stainless steel, aluminum and other difficult materials such as titanium.

For designers, engineers, and even business owners, finding out how laser cutting works and whether these devices can be effectively applied to the metal cutting process will be useful in making certain decisions and ensuring excellent results.