Can a Diode Laser Cut Aluminum?

As most metal cutting applications involve aluminum, this article will focus on understanding the capacity of diode lasers to provide cuts to aluminum and the effects and constraints of this capacity.

Diode Lasers: An Overview

Small semiconductor devices that radiate intense monochromatic and highly collimated light beams, diode learners, or laser diodes. Because of their relatively small size, low cost, and excellent efficiency, they are employed in numerous applications. The PN junction is a diode laser principle in which light generation is achieved by passing an electric current through which electrical and optical fields are combined.

Diode lasers can be classified into two main types: Fabry–Perot and Distributed Feedback (DFB) lasers. The most familiar type of Fabry-Perot laser employs multiple reflections and produces a wide-spectrum light beam. DFB lasers, on the other hand, are much more complex than Fabry–Perot lasers and have distributed grating, hence exhibiting light emission in a single mode and narrow spectrum, respectively.

Diode lasers can emit light at different wavelengths depending on the end user’s requirements. The most frequently used wavelength is 808nm, which is suitable for cutting and welding carbon steel and stainless steel. However, other wavelengths are also available in appropriate uses, namely 940 nm, 1064 nm, and 1320 nm.

Slicing of Aluminum through Diode Laser

The low density, rust-proof characteristics, and high thermal and electrical conductivity of aluminum make it an ideal material that could be widely used in various sectors today. Nevertheless, this metal is rigid to work with because of its high melting point and ability to reflect heat and/or light; to elaborate, mechanical cutting and plasma cutting are challenging to perform on aluminum.

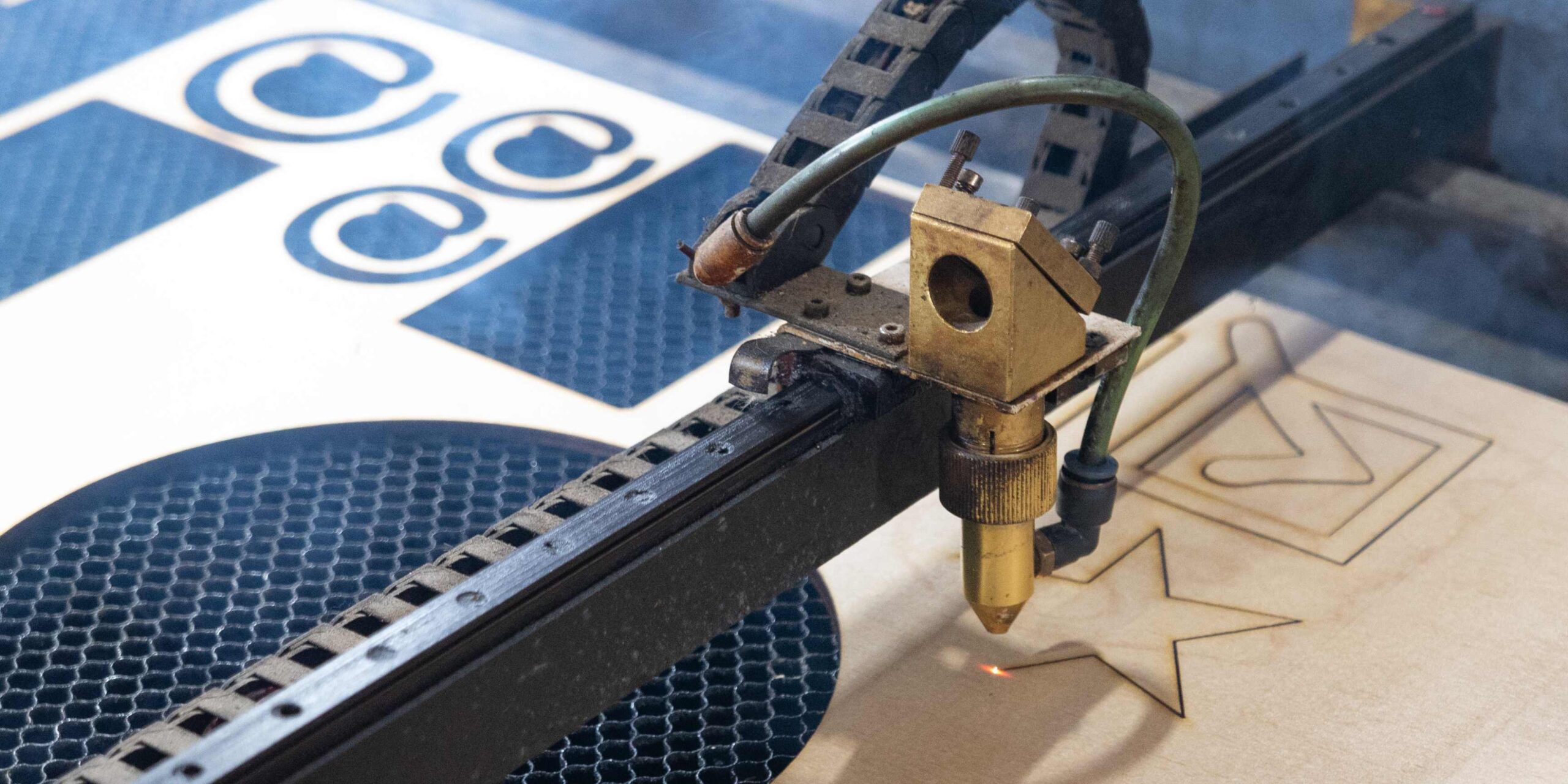

Today, laser cutting is widely used to cut aluminum as a better option to other methods. The operation of the laser on the aluminum surface lets the power density be high enough to melt or evaporate the material necessary to make a definite and clean cut. The parameters pertaining to laser cutting are laser wavelength, laser power, laser spot size, laser speed, and the nature and thickness of the aluminum.

Diode lasers are not popular for the cutting of aluminum and this is because; though the diode lasers can be used for cutting of aluminum, it can only be done if the correct parameters have been applied. For clean and smooth cutting of aluminum material, a diode laser should have high power-rated output, most preferably above 1kW, and concomitant laser wavelength of the diode laser should be easily absorbed by the metal material. Other laser parameters should also be adjusted to the spot size to equal the cutting speed and edge quality.

Application of Diode Lasers to Cut Aluminum: Strengths and Weaknesses

Diode laser which is cheaper is more suitable for small and medium enterprises than CO2 or fiber lasers. Furthermore, diode lasers are characterized as having a long useful life and low level of maintenance, which makes them cost-effective devices.

However, some drawbacks can be observed when using diode lasers for cutting aluminum. Cutting process is likely to occur at higher rates of power and at slower rates at times compared to other lasers. Consequently, production time and power utilization may be increased.

Further, it is discovered that diode lasers are likely to give a marginally inferior cut quality when used on aluminum, particularly on thick material or complex shapes. Another disadvantage of diode lasers may be a higher size of the heat affected zone compared to conventional lasers which can extend its adverse effects on the material surrounding the cut.

Although diode lasers can cut aluminum, one should not use them in the situations where accuracy is paramount, or where the aluminum is particularly thick. Other similar types of laser that can work better are CO2 or fiber laser in relation to the rate of cutting, sharpness of the edge and minimized heat affected zone.

Characteristics of the cutting process and factors influencing it

Several factors can influence the quality and efficiency of diode laser cutting in aluminum, including:

1. Laser wavelength and absorption: The optical absorption coefficient of laser light by aluminum is not very high, especially in the near-infrared range of wavelengths (800 – 1064 nm) standard to diode lasers. Higher power losses and lower cutting rates can follow. To enhance the absorption some changes in the laser parameters or a surface coating may be applied as a part of the preprocessing stage.

2. Laser power and focus: The material cutting rate and edge quality all directly depend of the chosen laser power and focus. By use of higher power levels and finer spot sizes, the cutting speeds are always higher, and the edge quality is well enhanced. Nonetheless, the most suitable laser parameters with regard to thickness and quality of aluminum could be different.

3. Cutting speed: There is a strong correlation between the cutting speed and quality of cut and the heat affected zone. Increasing cutting speeds makes the cuts smoother, and also reduces the amount of heat that causes degrading of the edge, but it reduces the cutting performance in equal proportion. Proper control of the cutting speed suited to a particular job is absolutely critical in order to provide the highest possible value of the ratio between the speed and accuracy.

4. Assist gas: The cutting operation is made better by removing molten metallic and chips from the area being cut by using an assist gas like nitrogen or oxygen. Cutting speed and edge finish will vary, depending on the type of assist gas metered and the pressure used.