Can you cut aluminum with a laser?

How Lasers Cut Materials

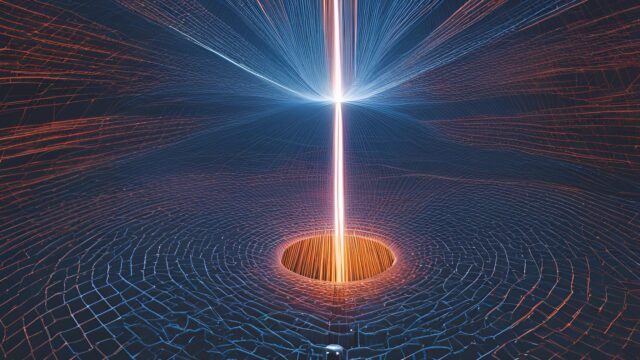

A laser – A concentrated beam of light power

Lasers direct a very high-density, slim stream of light energy to a specific area. This concentrated energy puts the heat intensively and rapidly on any target material, making it melt and vaporize. During the scanning process, the laser beam also maintains a cutting process through ongoing melting and vaporization of the material.

Computer numerical control for accuracy

Today, laser cutting machines are controlled by computer numerical control (CNC) technology to prevent the head of the laser. This enables making immaculate and accurate cuts to even hard-to-shape mass through the material. The thickness, speed, and beam power are variable to establish the proper cutting mechanism for the various forms of material.

Conditions Involving the Process of Cutting Aluminum with Lasers

Material Thickness

Less thick aluminum can be cut with relative speed. The thickness of the aluminum influences the laser cutting in terms of possibility and speed. Some users cut much thinner sheets that are slimmer than ¼ inch, and they need laser power to make the cuts. Thicker blocks require high-power lasers, low cutting speeds, and possibly several passes to complete the cut.

Alloy Composition

The combination of high iron or copper content spikes up the troubles. The cut material melts when subjected to the lasers. It took more laser energy for high iron and copper-containing aluminum alloys to cut because they have a higher boiling point than an alloy with a lower iron and copper content. Pure aluminum grades are more easily vaporized and cut through with lasers than are the alloyed varieties.

Desired Cut Quality

It also means that higher quality cannot simultaneously be associated with lower speed. The inclination of the cut aluminum should ensure that a fine finish of the edges is produced without the laser being rugged. One simply has to reduce the speed at which one is cutting and also fine tune the power and focal distance to get a perfect laser cut edge. The fast-cutting aluminum leads to creation of rough edge.

Cutting Capabilities

It can get you very detailed, very intricate, tiny cuts. In brief, the most significant benefit of laser cutting is making fine cutting edges on the surface of aluminum with precise cuts. It cuts simple figures, combined shapes and contours with great precision and ease, small and complex holes, and slits are simple for a correctly set up laser cutter. The cuts display high edge quality when implemented in an optimal manner.

Limitations

Difficulties arise when the material is a reflective surface, e.g. its responses are given in reverse. An aluminum material has a glossy and reflective characteristic that bounces part of the laser power without cutting the material properly. This reflective nature implies that to energize the metal more power is required as compared to other metals. In addition, if aluminum is not prepared correctly, it turns into oxide when heated during the laser cutting process.

It takes high power to bend a thick aluminum. Aluminum thin sheets can be slit but thick blocks above 1 inch in thick are difficult for most industrial lasers. High powered lasers of few kW or even thousands of watts can gradually cut thicker aluminum blocks. Aluminium has an immense potential for heat dissipation and as the thickness grows it chases the heat away from the cut area.

Summary

- Lasers soften and evaporate in order to saw through aluminum.

- Through Computer control, it becomes easy to describe brutal, accurate cuts.

- Can cut tissue thin sheets, thick blocks have to use special high power lasers.

- The surface oxidation as well as reflectivity of the material influences the cutting.

When adjusted for optimal cutting speed and appropriate laser power, lasers in cutting the foils of aluminum all the way up to a few inches thick are feasible. For cutting aluminum, it is essential to use laser, as the method has an excellent level of precision and complexity to cutting patterns that cannot be achieved through other means. Laser cutting made at high precision shows new ways to produce various products through aluminum.