Types of Laser Cutters

Introduction

Laser cutting is one of the thermal fabrication processes that involves using laser beams to cut or melt materials. The concentrated light wave sears, fuses, boils, or discharges away material to carve complex shapes and graphics. Since laser cutters have such high accuracy and speed, they can be widely used in many industries such as manufacturing, construction, aerospace, automotive, etc.

Some of the current laser cutters have different laser technologies, power, control, moving systems, and so on. To help you envisage this, this article will give a brief overview of the standard laser cutters.

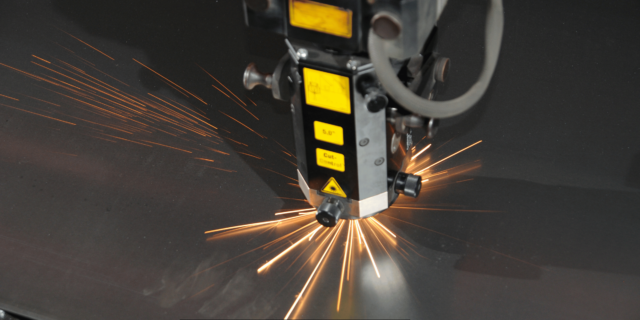

CO2 Laser Cutters

CO2 laser cutters are currently used as the premier laser cutters in the market today. As the name implies, they employ a sealed CO2 carbon dioxide gas as the active medium within a CO2 laser chamber to emit an Infrared laser beam.

The CO2 laser generator is made up of a cylinder that has been provided with a CO2 gas mixture, and when a high voltage is applied, the mixture emits an infrared light of wavelength 10. 6 microns. This infrared laser light is then focused through lenses on the workpiece placed on the laser bed to melt or vaporize the material.

In fact, CO2 laser cutters are machines used to cut wood, plastics, textiles, acrylic, leather, and many others. It can only shave through material not more than 1 inch thick, depending on the capacity. These lasers provide excellent edge quality and still generate neat, accurate cuts in a very short period.

Joint CO2 laser cutters:

– Low power (10-100 watts) – practical for engraving and thin materials such as wood or leather.

– Medium power (100-500 watts) for higher power density, which can create thicker materials up to 0. 25 inches.

– High power (500-1500 + watts) –For cutting up to 1 inch material

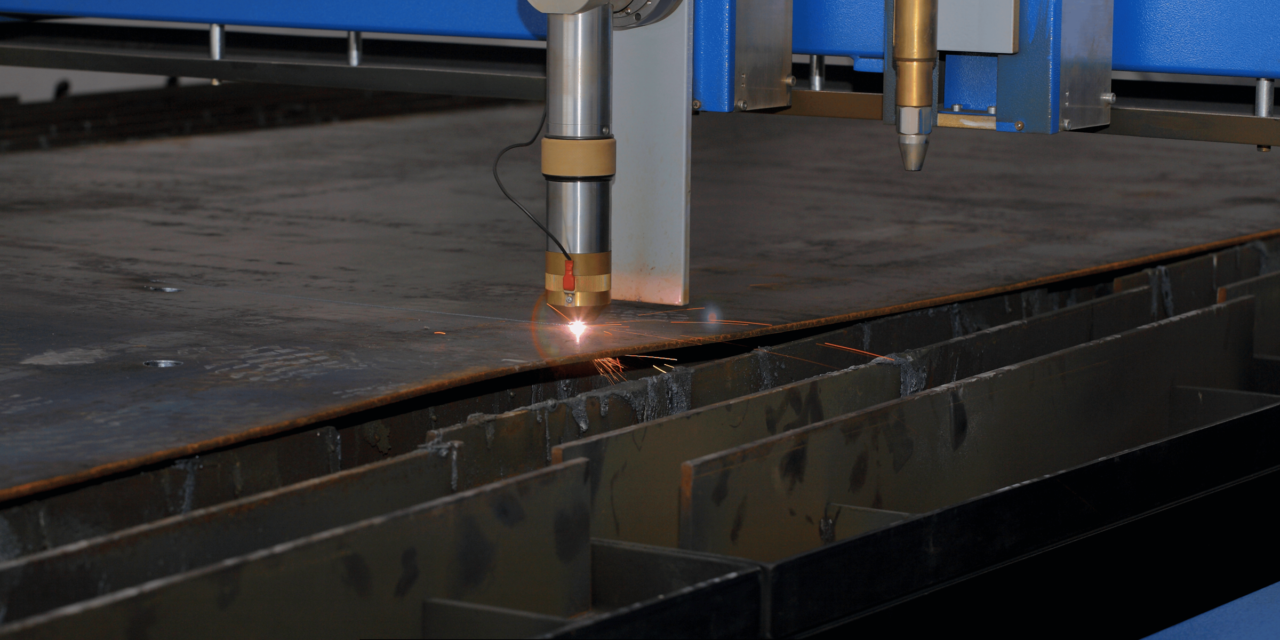

Fiber Lasers

Fiber laser cutters utilize glass fiber optic cables with rare earth, such as ytterbium, neodymium, and erbium, to create the beam. The fiber cable is then filled with the diodes to stimulate the active medium and emit infrared light at a wavelength of about 1. 05 microns

In general, CO2 lasers are less efficient and use more energy, while fiber lasers have better beam quality. However they encompass a more limited selection of materials like metals and some plastics.

Key benefits include:

– Higher precision cutting

– Faster cutting speeds

– Compact size and portable

– Lower running costs

– Cutting materials such as copper, brass, aluminum, etc, which are highly reflective, is possible with ease.

Fiber laser standards of output power can be between 100 watts and 6 kilowatts used for industrial purposes.

Diode Lasers

Diode laser cutters utilize semiconductor diodes that emit high-intensity laser beams within the visible and infrared spectrums upon the application of current. They work in a fashion analogous to a light-emitting diode (LED).

Certain benefits pertaining to the diode lasers include size, wall plug efficiency, life span, and cost. However, there are disadvantages in their beam power, and the quality of the beam is not very high either. Diode lasers are best utilized in low power operations such as welding of plastics, soldering, cladding, etc.

These machines can cut up to a capacity of 0. of 02 inch thickness. Output power control is mainly in the range of ten to one hundred watts.

Other Types

Some other niche laser-cutting technologies include:

Picosecond Lasers:

Create pulses of concise duration with a range of picoseconds for exemplary kerfing processes necessary for cutting fragile material less than 10 µm and drilling tiny holes less than 500 µm. Popular among the electronics and semiconductor industries.

Ultraviolet Lasers:

It uses wavelengths in the UV range, such as excimer lasers at 248 or 308 nm. Enables slicing of a wide variety of products without adverse effects from thermal damages for cases where the accuracy of results is of utmost importance.

Green Lasers:

Wavelengths were doubled in frequency, and infrared was converted to visible green light at 532 nm. This applies to the delicate substrates where heat impact must be addressed.

Conclusion

This means that the laser cutters come in all sizes and capabilities based on power, levels of detail, possible material, speed, and cost. The most common types of laser cutters that are used include the CO2 and fiber lasers, which appear to provide the best blend of performance and functionality, which are requisite for most uses. Choosing the right laser-cutting equipment is crucial based on the cutting requirement and the type of material to produce good outcomes.