From Concept to Creation: How Laser Cutting Machines Are Reshaping Engineering and Construction

Which role does the cutting machine with a laser in engineering and constructing play?

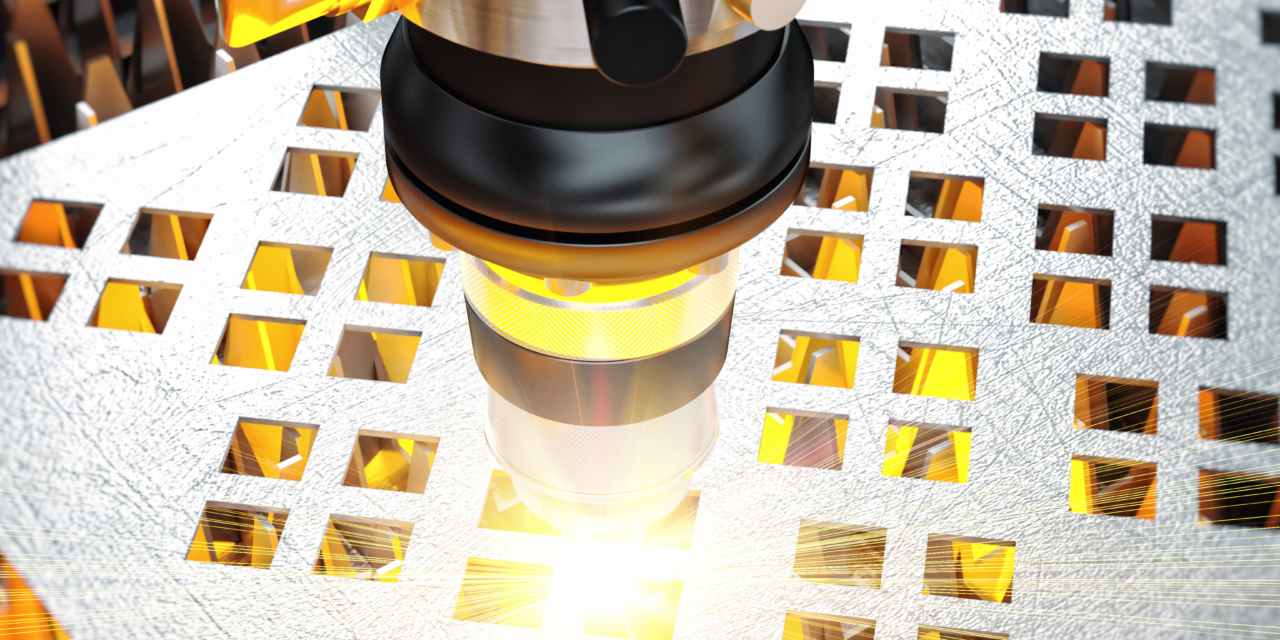

Laser cutting of machines used in engineering and construction have a variety of notable features and applications that have revolutionized the industry. These paramount devices are able to cut through numerous materials, such as metal, wood, and plastic with great exactness making it possible to design intricate patterns and almost any shape. They have only one major tool in their kits, which is high-powered lasers, and this enables them to work faster at lower costs while maintaining high product quality. These tools achieve the task in a very accurate manner and are inseparable from the production of complex architectures and prototypes. While these systems continue to develop with technological improvements, they will be able to bring about the next industrial revolution and the implementation of the dreams that engineers and construction professionals have.

In which specific ways can a laser cutting process be able to solve common problems in engineering and construction activities?

The technology of laser cutting machines with their strongly high-powered lasers solves the most daunting problems encountered during engineering and construction work. These sophisticated toys can accurately cut multiple materials such as metal, wood, and plastic thus making it possible to create sophisticated designs and complex shapes which were earlier considered impossible. These tools provide increased precision and productivity with relatively low costs and improved quality of products. With the help of precision cutting, it becomes possible to form components that were impossible to create before by human means due to the requirements of high accuracy and design complexity. As these machines keep on evolving with technological developments, there is a possibility that they are going to be more engaged in the remedy of the problems that engineers and construction personnel usually face.

What are the most popular laser-cutting machine applications in engineering and building assignments?

The engineers and the construction workers deploy laser cutting machines for a wide range and a number of projects. These advanced tools can be utilized for a wide range of purposes, including These advanced tools can be utilized for a wide range of purposes, including:

- Precision Cutting: Laser cutting machines are perfect if you want to very accurately cut through metals, wood, or plastics to create the precise shapes and components that are required in engineering and construction projects.

- Prototyping: Engineers and builders make use of laser cutting systems to develop prototypes and models of their designs as quickly as possible, which then accelerates the testing and refinement of the concept before production.

- Custom Fabrication: Laser cutting machines allow for the creation of custom components and parts, thus it is possible to manufacture anomalous and complex designs that cannot be economically accomplished by traditional manufacturing means.

- Architectural Elements: Laser cutting machines are employed in construction projects for the creation of architectural components that have beautiful and intricate designs, examples of these include decorative panels, facades, and signage, which give these buildings and structures a new look.

- Metal Fabrication: The typical use of laser cutting machines in the production of metal components for engineering and construction purposes is cutting and shaping structural components, brackets, and fittings. Manufactured parts are highly precise.

- Rapid Prototyping: Laser cutting technology enables fast fabrication of prototypes and models and, thus, the development and application of new ideas and designs in an affordable and prompt way.

- Customization: These devices let you do things like tailor individual parts and pieces making it possible to fabricate special and complicated designs that you may not be able to achieve through other manufacturing methods.

Following all, a wide array of laser cutting applications in engineering and construction projects exists offering solutions for high-precision cutting, rapid prototyping, customized fabrication, architectural details, and more. These machines will further develop as time goes on, and their uses will continue even more which will bring an industrial revolution in the way the industrial engineering and construction fields carry their ideas out.

What are the ways available for engineers and construction professionals to create cutting-edge innovations using a laser cutter?

Utilization of the full potential of CNC laser cutting machines can open up many unseen possibilities for engineers and building professionals to use their design and flexibility in different innovative ways. The advanced tools with a variety of functions and possibilities permit great accuracy in the cutting of materials, metal, wood, and plastic, and make various pieces with different shapes, pieces, and components. An integral role of these machines is the application of lasers which results in highly productive operations with reduced costs and improved quality of the end products. Further, laser cutting machines offer quick prototyping, personalized components synthesis, as well as manufacture of architectural elements, hence creating space for the designer’s creativity and innovations in engineering and construction projects. Moreover, the development of these tools must not be confined since they will also play a key role in shaping the future of the industry.

Conclusion

To summarize, laser cutting machines provide an array of benefits and a chance to solve the challenges and come up with solutions for engineering and the construction industry. Their accuracy, flexibility, and speed enable them to be an irreplaceable tool for fabricating complex parts that answer to the needs in the industry, the challenges posed, and the innovation required in designing and building constructions and engineering projects. While implementing the capabilities of laser cutting machines, professionals can move the industry boundaries and push to achieve more.